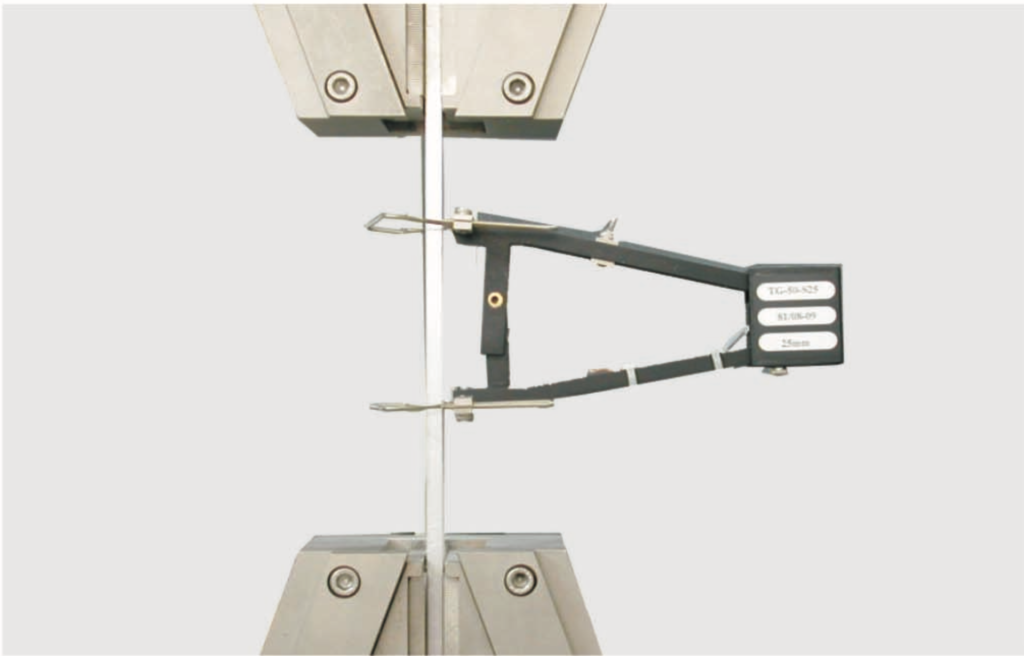

Clip-on Extensometer

Clip-on strain gauge type of extensometer provides cost effective solution for extension measurement. It includes different gauge length and strain range options to suit a wide range of specimen characteristics. These extensometers offer speed of attachment and ease-of-use. The light-weight, rugged cross-brace design eliminates errors caused by physical distortion, while built-in protection ensures that damage is not caused by over-extension.

KEY Differentiator

Clip-on gages are used for a variety of fracture mechanics tests, including compact tension, arc shaped, and disk shaped, bend specimens or other specimen geometries in compliance with ASTM and other standards organization’s test methods. Clip-on gages can be used directly on test specimens where the knife-edges are integral with the test specimen or, alternately, with optional bolt-on knife-edges mounted on the test specimen. The extensometers can be installed or set in place accurately and consistently with rubber cord, ensuring speed and reliability of operation. These extensometers are used to measure positive strain of tensile testing.

The extensometers have a cross-flexure design. This design assures true center – point bending and provides these important test features:

- Low activation force, typically under 60g and as low as 30g

- Small lightweight design-most are under 70g mass.

- Low hysteresis -typically under 0.1 %

- Exceptional linearity, especially through zero t ravel

- Extended travel capability-up to 1 inch (25mm)

- Fully enclosed gages to protect from accidental damage.

- All standard units meet existing ASTM requirements for accuracy.

- Includes high quality foam lined case.

Gauge length: 25mm, 50mm, 100mm and 250mm

Extension (Span): Range 4 – 25 mm

Resolution: 0.001 mm (Lower resolution option available uptil 0.01μm)

Accuracy: ±0.1% at gauge length

The extensometers have features and capabilities that make them useful a vast range of tests.

1. Metal tensile testing

2. Rigid plastics tensile testing

3. Composites tensile testing

4. Polymers

5. Wood

6. Rubber

7. To determine E modulus, n value, (proof strength) Rpxx, and percent elongation

And other materials of both extremely low and high strength at both high and low strain levels, a unique design that expands your test capabilities.

Axial & Transverse

- For measurement of Poisson's ratio for transverse measurements used simultaneously with Dak's axial extensometers.

- For anisotropic materials like composites, for sheet metal testing and determination of the

r-value.

Self-supporting on the test sample

These extensometers will work on any width or diameter specimen from 0 to 1 inch (25 mm)

Various Extension Ranges

- Extension Range 4 mm- 25 mm

- Gauge-lengths of 10 mm-50mm

- Resolution of 0.001 mm

Stability

- Held in place with an integral spring and the rounded contact edges maintain the position on the specimen