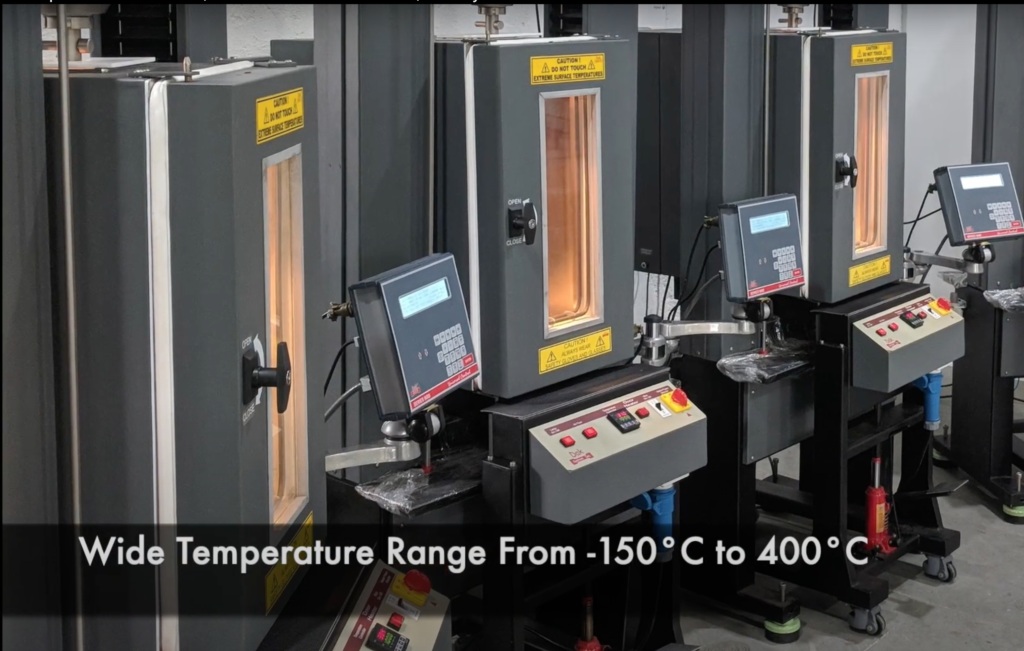

Temperature Chamber

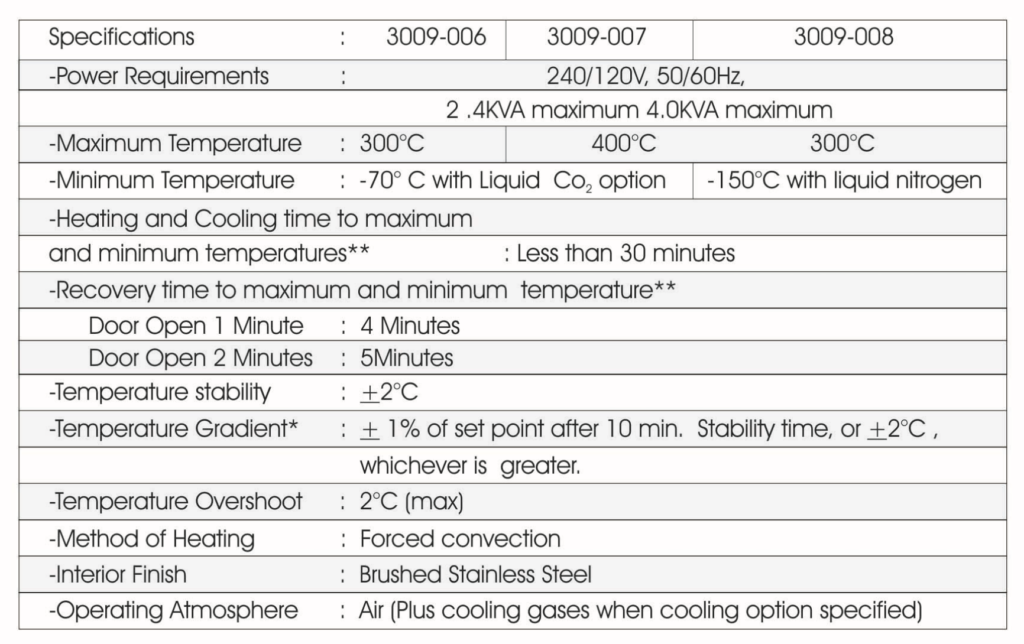

Temperature range from -150 to + 400 deg. C. Various models is available to suite the required temperature range. Lifting & moving trolley can be provided for portability of test chamber.

The wide range of environmental chambers provides extensive temperature testing capabilities for evaluating material properties under non-ambient testing conditions. A full range of complementary grips and pull rods is available.

KEY Differentiator

Principle of Operation

The chambers use forced convection heating for optimum temperature distribution and sophisticated controllers ensure minimum overshoot and excellent set-point stability. Features such as internal lights and trolley mounting options ensure ease of use.

Application Range

– High and low temperature testing of materials and components in tension, compression, shear, flexure, fatigue etc

- Temperature ranges from –70 to +400°C

- Optical quality heated viewing window

- Mounting brackets (movable trolley for ease of use and removal of chamber)

- Variable speed circulation fan

Designed for use with Extensometers

The chambers are designed for use with contacting and non-contacting extensometers. The interior is finished in brushed stainless steel to provide a contrasting background for video extensometry. The door has a multi-pane optical quality high temperature boro-silicate glass window, with a heated outer pane to reduce condensation during low temperature testing.

Versatile Mounting

The environmental chambers can be mounted onto the load frame in a fixed position. Alternatively, a trolley mounting assembly enables the chamber to be moved clear of the working test area.

A lift stand is available to assist in the installation of the temperature chambers. By using the lifting brackets provided, the lift stand can be used to raise the chamber to the required height for mounting on to the load frame.

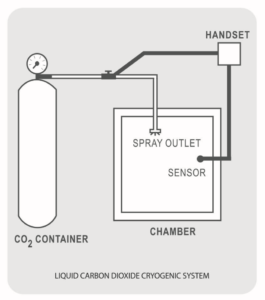

Low Temperature Testing: Cryogenics

The series 3009 environmental chambers can be operated at below ambient temperatures using one of the optional cooling packages, dependent upon the cryogen used. Liquid carbon dioxide is used for temperatures from ambient to -70 °C. Liquid nitrogen may be used from ambient to -150 °C, dependent upon the type of chamber. The cryogen is sprayed into the chamber near the fan to ensure even distribution. When the desired temperature has been reached, the temperature controller will regulate the liquid flow with a solenoid valve. The chambers incorporate an exhaust port, which allows the waste gases to be safely ducted to a well-ventilated area for dispersal.

Precise control

Two methods of heating or cooling the chamber to the desired temperature are available for either short cycle time or slow heating or cooling rate. The normal automatic self- tuning PID (Proportional +Integral + Derivative) control enables the chamber to reach the set point temperature in the shortest possible set time.

Variable Speed Fan:

An impeller inside the chamber ensures even distribution of air, maintaining an even temperature. All chambers incorporate a variable speed fan, which allows the user to reduce air turbulence during the testing of delicate specimens. For short tests, the fan can be switched off.

Precise Control:

Two methods of heating or cooling the chamber to the desired temperature are available for either short cycle times or for slow heating or cooling rates.

Variable Speed Fan:

An impeller inside the chamber ensures an even distribution of air, maintaining an even temperature

Cryogenics:

- For below-ambient temperatures by using cryogenic liquid CO2.

- The chamber incorporates an exhaust port which allows the waste gases to be safely ducted to a well-ventilated area for dispersal.

Lift Stand:

- A Lift stand assists in the installation of the temperature chambers.

- With lifting brackets the lift stand can

be used to raise the chamber to the required height for mounting onto the load frame.