Rubber Process Analyzer

The Rubber Process Analyser (RPA) is a sophisticated yet simple to use testing equipment for measuring the viscoelastic properties of various polymers and rubber compound before, during and after cure giving a detailed analysis of Processability, Cure characteristics & Final cured properties.

Criteria for selecting RPA:

1. High strain processability testing.

2.Sealed pressurised cavity permits higher shear rates and applied strains.

3. Ease of Use.

4. Current Function.

5. Can measure other in-process properties (ie. cure characteristics) in a single Test.

6. Ease of removal of samples (film can be used with very low viscosity or sticky samples when tested at lower strain).

- Enables the test to be performed under Variable Strain, Variable Frequency & Variable Temperature.

- Precise temperature control system with cooling option.

- High Resolution Direct Drive system provides high stiffness high accuracy in strain control.(Resolution:0.0003 arc degree)

- Sealed and pressurized test cavity.

- Robust, sensitive torque transducer.

- Frequency Sweeps, Strain Sweeps, Temperature Sweeps, Cure Tests, Stress Relaxation, Variable Temperature Analysis, Timed Tests.

- Direct Drive & “Dyna Pro” software enables to directly set the oscillation angle removing the need of physical adjustment/ replacement of the spacers hence eliminating the requirement for re-calibration.

- Choice of unit systems: Torque Units dN.m, lbf.in, kgf.cm or Nm &Temperature Units in either ˚C or ˚F

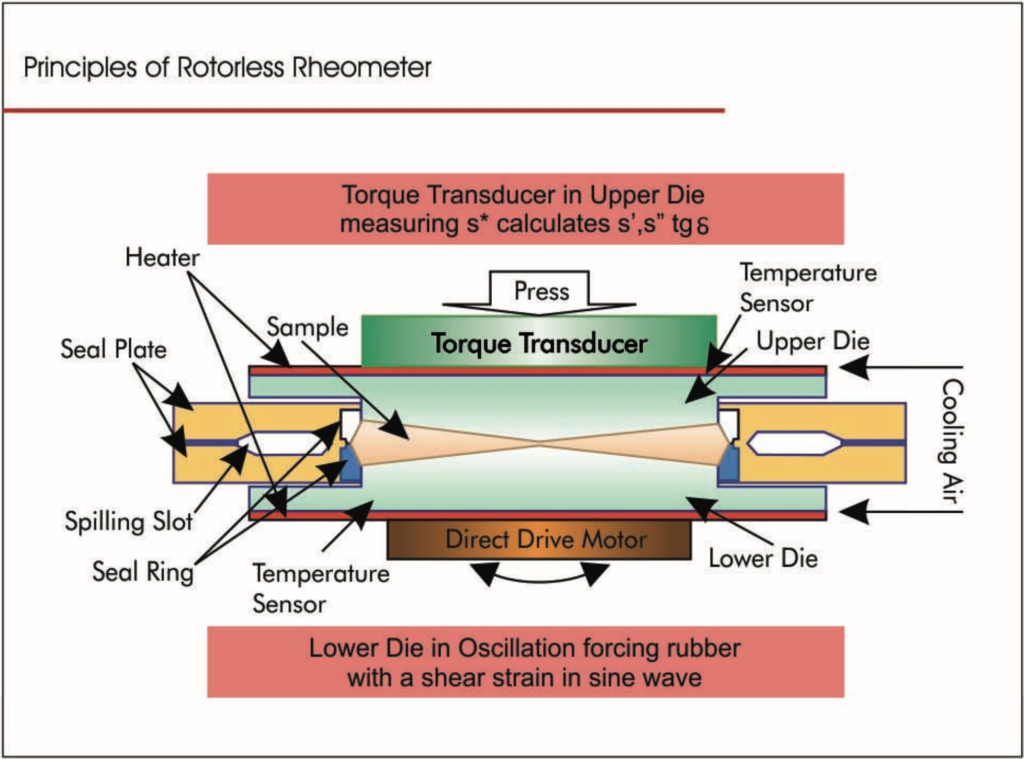

PRINCIPLE OF OPERATION

- The RPA 4500 is a dynamic mechanical rheological tester (DMRT) specially designed to measure the dynamic properties of raw polymers, uncured compound and cured compounds The RPA 4500 applies a sinusoidal strain at a programmed amplitude and frequency in a sealed, pressurized cavity.

- The oscillation frequency can be set from 0. 1 to 2000 cpm (cycles per minute), The magnitude of lower die movements is set to an angle of oscillation which generates the required strain on a sample B The lower die can oscillate from + 0.05

to + 90˚ degrees of arc this angular oscillation corresponds to a strain of 0. .7% to 1256%. Because of this special sealed cavity,

very low & very high strain amplitudes and frequency can be applied with very good repeatability. The upper die is attached a torque transducer shows a torque response from the sinusoidal strain applied to the rubber specimen.

- Isothermal Cure

- Non-Isothermal Cure

- Isothermal Curing at Variable Strain

- Isothermal Frequency Sweep

- High Strain Non-Linear Behavior

- Strain Sweep for Filler Loading

- Time Dependent Structure Breakdown

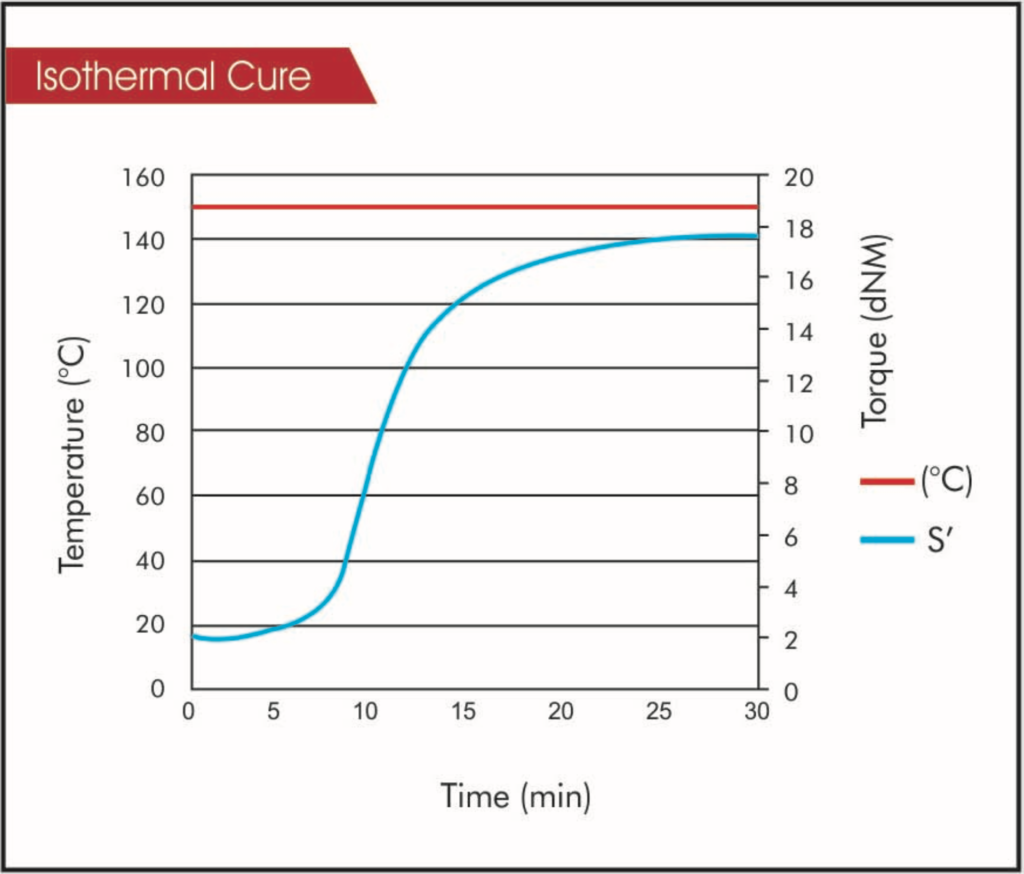

lsothermal Cure

- Isothermal cure experiments are critical for rubber & elastomer processing. Dak's latest RPA 4500 series provide high precision data that is simple to analyse. All the important characteristics, such as minimum and maximum

viscosity, scorch time, and conversion time are calculated easily and

automatically. The data can also be handled completely graphically for

comparison or alternative analyses.

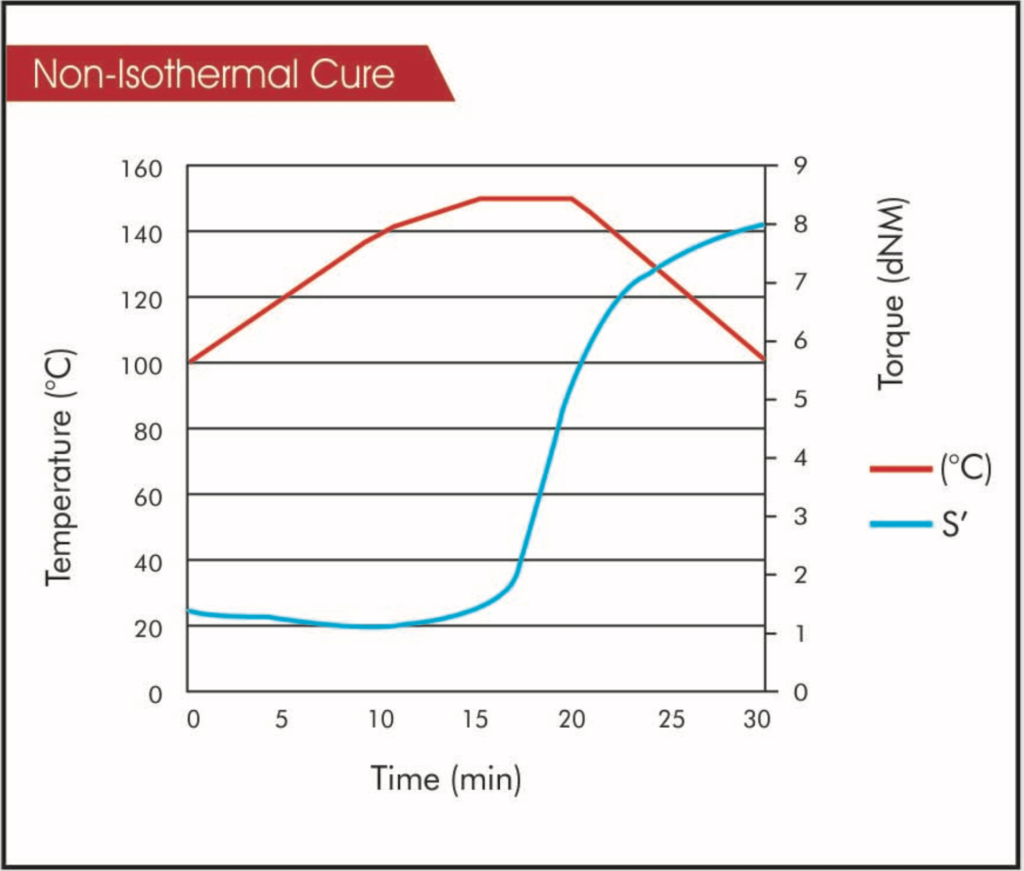

Non-lsothermal Cure

- In addition to industry-standard isothermal .cure methods, the RPA can perform non-isothermal cure experiments. These experiments can be programmed to follow virtually any 'temperature profile and are especially

valuable when simulating manufacturing processes that are not isothermal.

Non-isothermal curing experiments may also be coupled with isothermal tests such as strain and frequency sweeps before or after cure to provide a more

complete material data set before, through, and after cure.

Isothermal Curing at Variable Strain

- While standard test methods often call for a single strain and frequency value to be used for all materials (O.5", 1.67Hz), these are not always the ideal conditions for the material. In the present example, the sample material is tested by isothermal cure at three deformation amplitudes, five times each. At the standard of 0.5˚ and 0.4˚ the experimental variability is extremely broad. This is because these experiments are performed at strains beyond the linear viscoelastic limit for this material. Testing at a smaller amplitude (0.3˚) produces valid data with greatly improved reproducibility.

Most Popular Test Options :

Combination of D6204 & D6601 in one test ASTM Test Templates.

ASTM D6204 Processability:

- Frequency sweep at 7% strain

- Frequency sweep at 100% strain

- "Triple Play Combination of D6204 & D6601 in one test ASTM Test Templates.

ASTM D6601 Post Cure Dynamic Properties.

- Post-cure dynamic properties

- "Triple Play" of ASTM D 6604 & 6601 combination in one ASTM template.

- Strain sweep at 1 Hz and 100˚ C or 60˚ C

Choice of Units

Torque Units dN.m, Ibf.in, kgf.cm or Nm & Temperature Units in either ˚C or ˚F.

Acute Die Alignment

Gives an excellent die cavity sealing ensuring high repeatability.

Temperature Efficiency

Uniquely designed heater to reduce temperature gradients and improve temperature recovery.

Torque Cells

Torque Range 0.001 to 22.5 Nm