Moving Die Rheometers

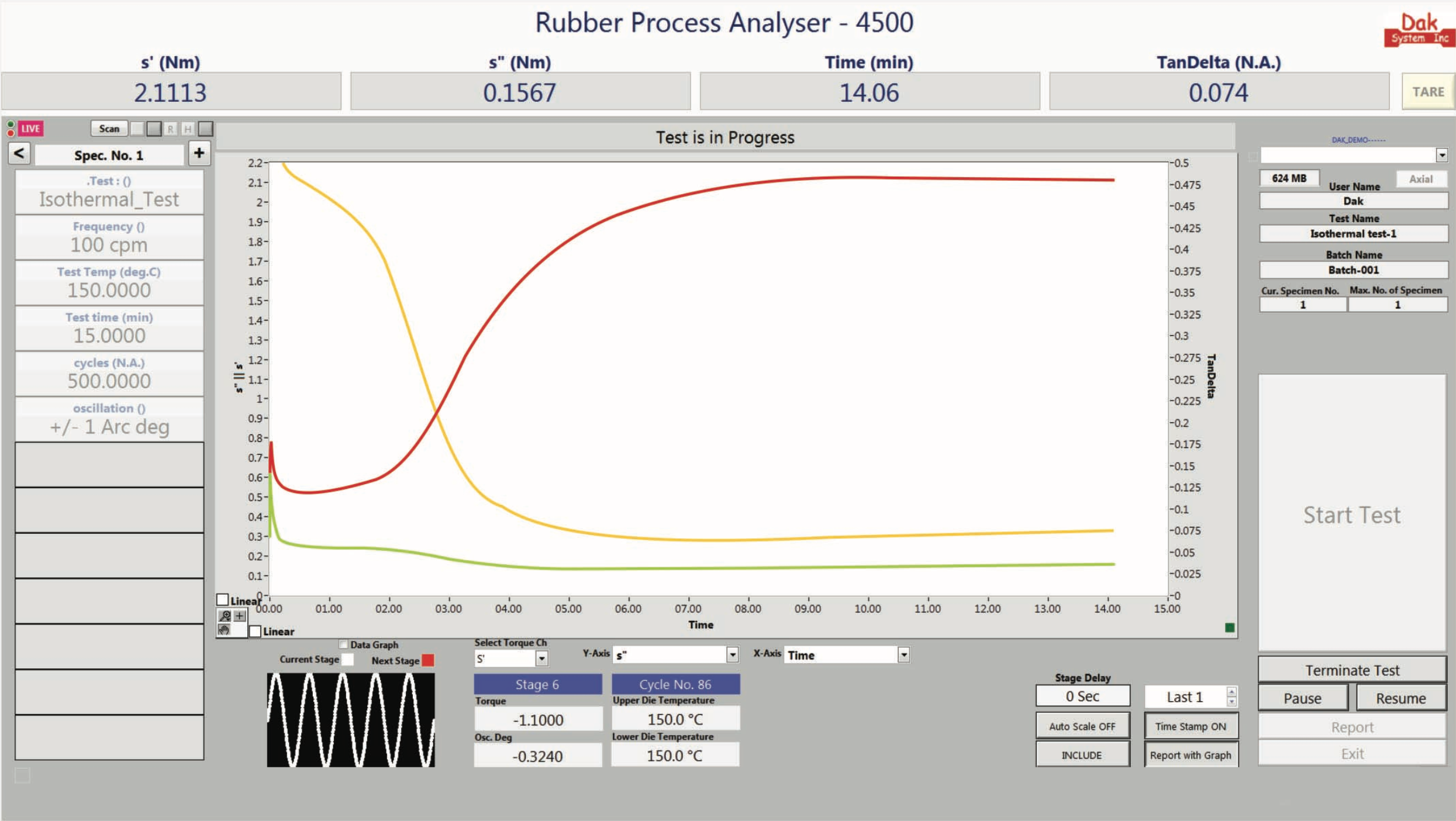

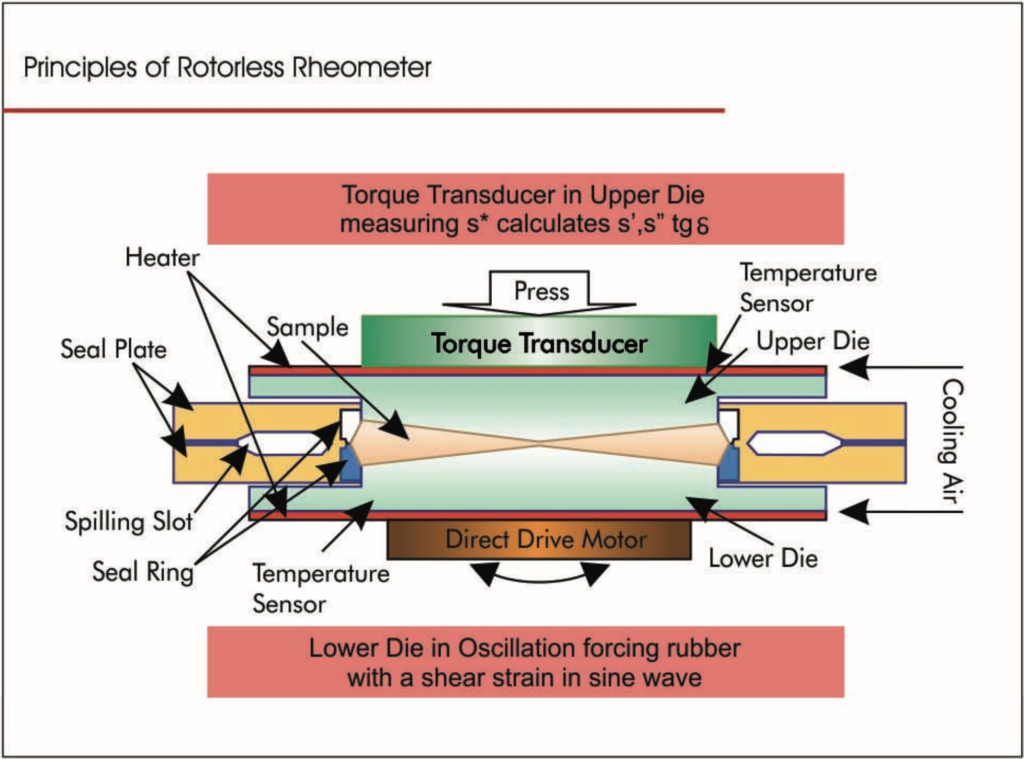

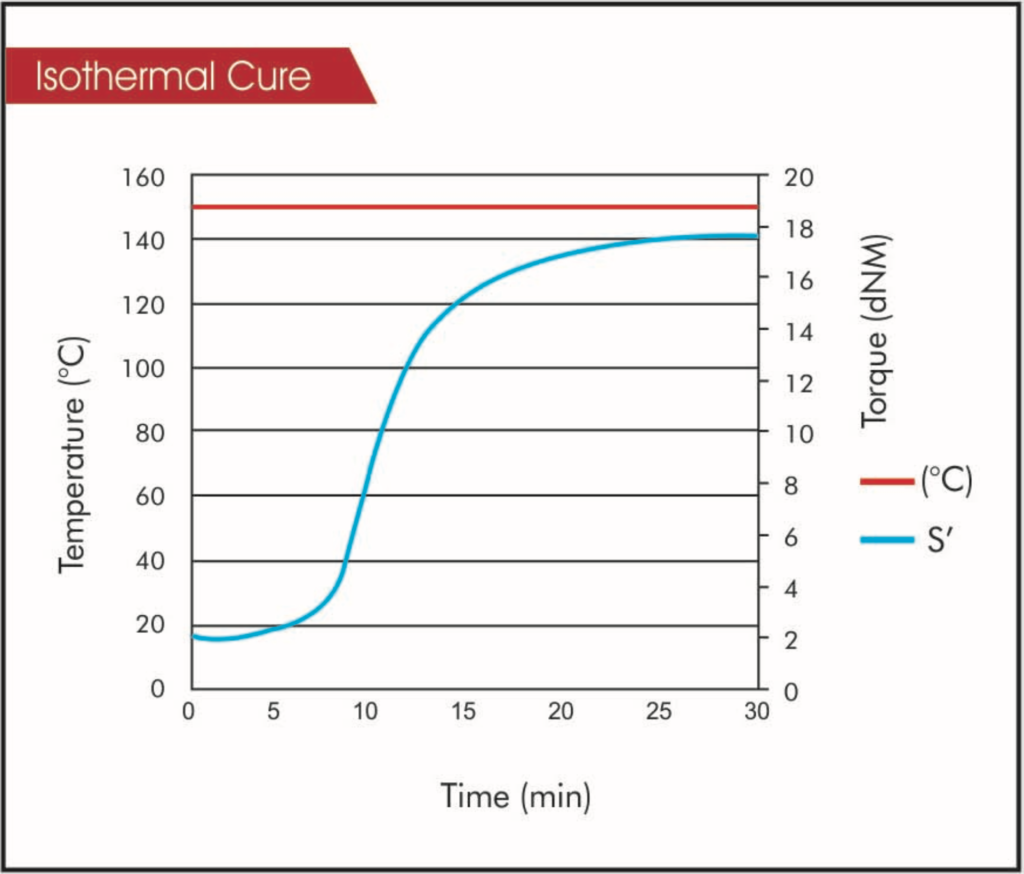

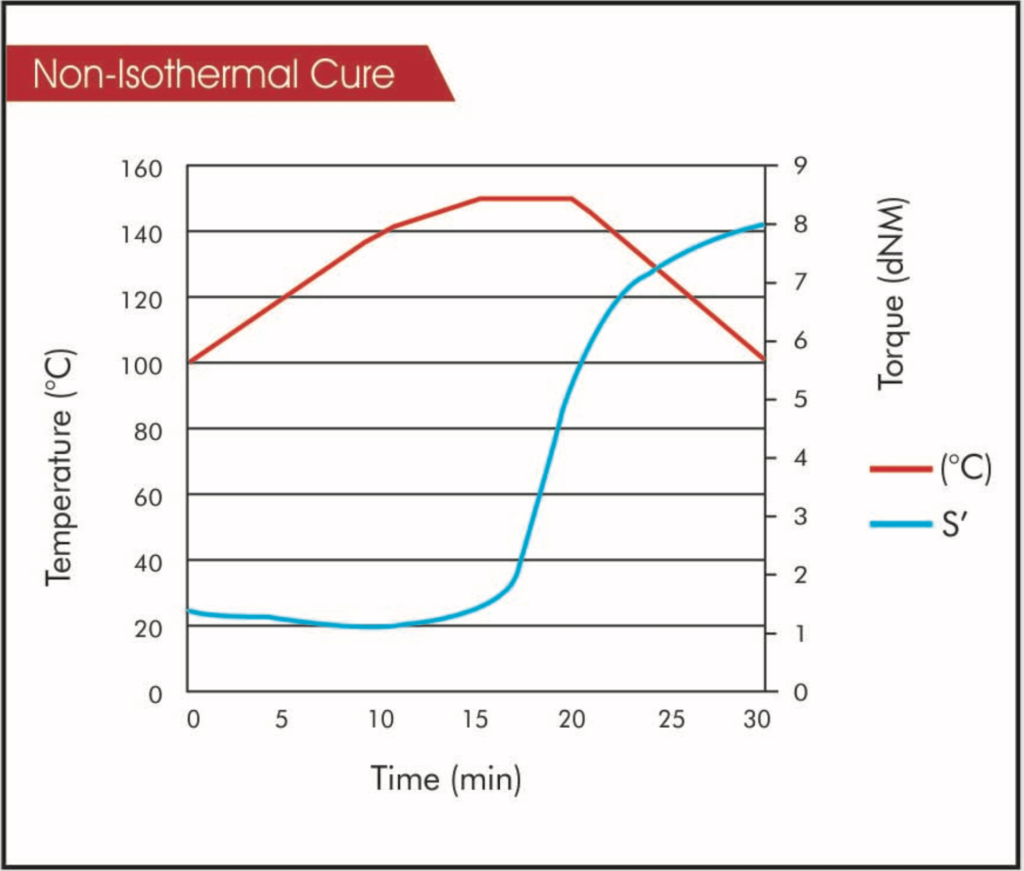

MDR Elite 6300 : is a rotorless curemeter that is reliable, accurate, and easy to operate. It is specifically designed for routine and standards-driven testing of rubber curing. The device is capable of measuring curing profiles of rubber compounds under isothermal and non-isothermal test conditions at a constant strain and frequency. MDR Elite 6300 consists of sealed biconical dies that meet all relevant ASTM, ISO, and DIN standards, ensuring accurate and consistent results.

The device has a unique design that includes an ultra-rigid test frame, a direct drive motor, and precision temperature control with optional cooling system. Additionally, the MDR Elite 6300 comes equipped with intuitive Control and Analysis software, which makes it an ideal platform for both QC and R&D environments. With its advanced features and reliable performance, MDR is a top choice for those in the rubber industry.

KEY Differentiator

- Direct Drive System

- ASTM D5289, ISO 6502, 13145; DIN 53529

- Option for Cooling system

- Biconical Sealed die design is employed as an industry std

- High pressure pneumatic sealing system

- Amplitude: ±0.1°, 0.2°, 0.5°, 1.0°, 3.0°, 5.0° arc

MDR Elite 6300

- Direct drive & “Dyna Pro” software enables to automatically set oscillation angle thus removing the need of physical adjustment/ replacement of spacers and eliminating the requirement for re-calibration.

- Measures isothermal & non-isothermal cure properties (Non- isothermal is optional as it is available only with cooling option).

- Advanced Symmetry of the upper crosshead with a four post design giving a rigid and sturdy system.

- Choice of Unit systems: Torque Units: dN.m, lbf.in, kgf.cm or Nm & Temperature Units in either ◦C or ◦F.

- Acute Die Alignment giving an excellent die cavity sealing ensuring high repeatability.

- Uniquely designed heater to reduce temperature gradients and improve temperature recovery.

- The test frame of the equipment is extremely rigid, ensuring accurate and compliance-free data.

- The equipment boasts unmatched precision, accuracy, and reproducibility of data. It achieves this through the use of a robust and field-proven torque transducer that guarantees high stability and reliable torque measurements.

- The use of pneumatic locking cylinders further enhances the equipment's performance, as it ensures repeatable sample sealing.

- The equipment comes equipped with powerful and intuitive user friendly Software, which is available in multiple languages.

- Additionally, the equipment allows for user calibration and user-replaceable seals, which not only increases its lifespan but also reduces maintenance costs.

- The combination of these advanced features makes this equipment a top choice for those in the industry seeking reliable and accurate results.

- The device offers over 100+ different process parameters like: ts1, TC10, TC50, TC90, S’min, S’max, scorch time, cure rate, and viscoelastic properties including: G’, G”, G*, S’, S”, S*, tan δ, η’, η”, η*

DIRECT DRIVE SYSTEM

- The MDR employs a direct drive motor that enables precise deformation of the sample.

- This Direct Drive system ensures that accurate and consistent deformation is always applied to the sample.

- The accuracy and precision of rheological or dynamic measurements rely heavily on the accurate application of constant deformation at a specific rate, step or periodic interval.

- Hence MDR can provide a highly reliable and repeatable data for various testing requirements.

COOLING SYSTEM

- The Standard Air Cooling System is designed to enhance temperature stability during testing.

- By blowing air at room temperature on both the cavities at 5˚C to 10˚C ambient air, the system can speed up temperature changes above ambient conditions and maintain stable temperatures near room temperature.

- This allows for more precise and reliable testing results, especially in applications where temperature control is critical.

Choice of Units

Torque Units dN.m, Ibf.in, kgf.cm or Nm & Temperature Units in either ˚C or ˚F.

Acute Die Alignment

Gives an excellent die cavity sealing ensuring high repeatability.

Temperature Efficiency

Uniquely designed heater to reduce temperature gradients and improve temperature recovery.

Torque Cells

Torque Range 0.001 to 22.5 Nm