Fatigue Testing Machine

Fatigue test is used to determine whether any material can withstand Cyclic Fatigue Loading. Repeated loading & unloading in various modes like tension, compression, bending, torsion, or multiple combinations of these tests can be used in cyclic fatigue analysis.

DAK’s versatile Fatigue series offers a range of applications meeting the testing requirements across industries with it’s diversified software capabilities & more than 400+ holding fixtures facilitating the testing of various materials.

The aim of a fatigue test is generally to determine the lifetime of a material subjected to cyclic loading, but fatigue strength and crack resistance are also frequently sought values. The cumulative number of cycles that a material can be exposed to under a single loading scheme is known as its Fatigue life. A fatigue test can also be used to assess the maximum load that a sample can sustain for a given number of cycles. All of these properties are critical in any industry where a material is subjected to changing rather than constant forces

There are several different forms of fatigue testing, as well as two different types of fatigue testing:

– Load controlled High Cycle Fatigue

– Strain controlled Low Cycle Fatigue.

High cycle fatigue tests are usually associated with loads in the elastic regime.

Low cycle fatigue tests are typically associated with plastic deformations.

Almost all materials might undergo Fatigue in some form or another across the lifetime of their application. Due to the rigidity and ductility, components made of metals or composites with these characteristics appear to have increased fatigue strength, these materials have a higher fatigue limit than others. Other materials, such as polymers, ceramics, and wood, may experience fatigue & must be tested to determine how they will respond to these unusual stress variations.

KEY Differentiator

Drive & motor system, Loadcells, Software & electronics, with a slick state of the art design & powered with high safety package offers a noiseless & accident proof testing experience.

Fatigue Application Industries

Hydraulic Actuator System

- Dynamic force rating for Axial.

- Displacement sensor for control of actuator displacement with displacement monitoring of 1 micron

- Axial servo valve of min 12LPM

- System has test specimen protect feature during test setup

- Nominal noise rating of 65 dB or lesser

- Interlock for over- temperature and low-fluid level protection.

- Waveform frequency from 0 to 250 Hz or higher.

- Fatigue Test for Cardiovascular Stent

- Accelerated Fatigue Life Tests (SSALT) of Dental Implants

- Ankle Prosthetic Durability Fatigue Test System | 810-22675 Model

- Dental Implant Fatigue Test Equipment

- Fatigue Testing Spine Implants

- Fatigue Testing the Tibial Tray Component

- Fatigue Testing Tibial Bearing Components

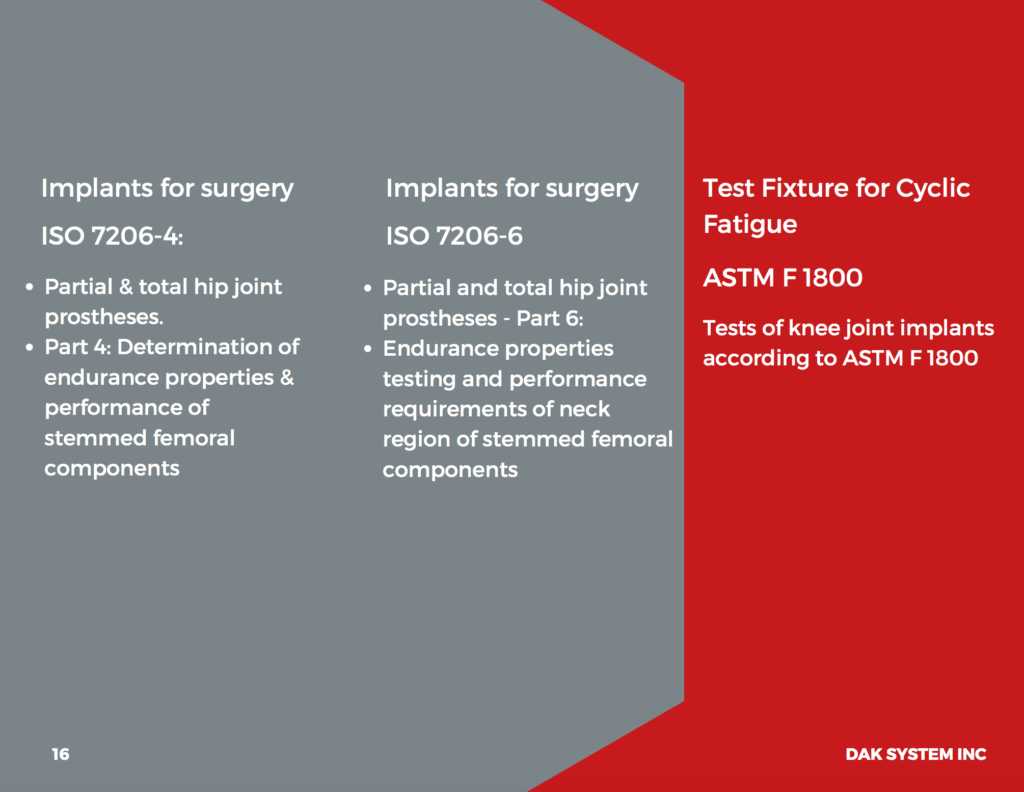

- Hip Implant Fatigue Equipment as per ASTM, ISO 7206

- Hip Implant Fatigue Testing Femoral Head, Stem, Acetabular Shell and Linear

- Fatigue Test Equipment for Polymer Matrix Composites

- High Elongation Tensile and Fatigue Test of Silicone Rubber

- Rubber & Elastomer Fatigue Test Machine

- Testing Rubber and Elastomeric Dynamic Vibration Isolators

- Ceramic Matrix Composites Fatigue Test Equipment

- Fatigue Test Machines for Honeycomb Composites

- Fatigue Testing of Ceramic Matrix Composites

- Honeycomb Composite Fatigue Test Equipment

- Low Force Electrodynamic Fatigue Test Machine

- Testing Metals for Thermo Mechanical Fatigue (TMF) Life

- Stainless Steel Fatigue Cryogenic Tests

- Metals Fatigue Testing at High Temperatures

- Metal Matrix Composites Fatigue Test Equipment

- Metal Chain Static and Fatigue Test Application

- Low Cycle Fatigue (LCF) of Metals at High Temperature

- High Cycle Fatigue (HCF) of Metals High Strain Rate

- Fatigue Testing Metal Matrix Composites

- Fatigue Testing at Cryogenic Temperatures

- Strain Controlled Low Cycle Fatigue Testing Equipment

- Fatigue Test Machine for Cold Environments

- Water Pressurization Fatigue Test System

- Aircraft Structural Testing

Basic Safety Package

•Mechanical Over Travel Limits •Emergency switch with Lamp •Over Load Safety Mode

Power Saving Mode

• Programmable Sleep - Auto Sleep mode Activation

• Power down mode - Auto switches OFF the complete system

Dual Mode Operation

Dual mode Operation

•For operating the machine view Live graphs of the tests online.

•With PC system - Storing the test results for analysis.

Software Key Benefits

• Follow Me Mode

• Four Control Modes

• Special Safety Features

•Formula Editor

• Report Customization

• Ready to use Tests

• Flexible Testing Units