UNIVERSAL TESTING MACHINE

Series 7200 - The Advanced Model

This is a Gen-NXT series of material testing machine, built to offer the smoothest testing experience, repeatability & analysis. Assuring you test results with minimum human effort & powered by technology & software.

KEY Differentiator

Drive & motor system, Loadcells, Software & electronics, with a slick state of the art design & powered with high safety package offers a noiseless & accident proof testing experience.

- Loadcell Accuracy starting from 0.005%

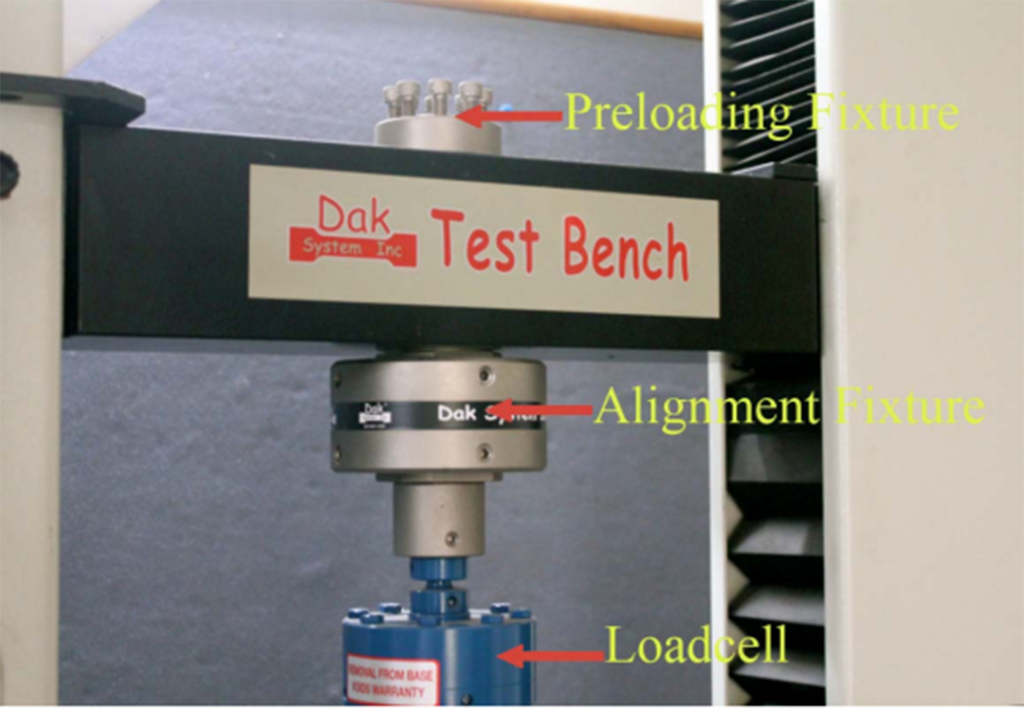

- Provision for alignment of load trail as per ASTM E 1012 Class 5 is available.

- All our load-cells are temperature compensated.

- All our data channels are 24 bit i.e. equivalent to 1,67,77,216.

- Dak controller after applying digital filters is able to achieve data resolution up to 1/80,00,000.

- Dynamic stiffness compensation virtually giving machine stiffness of less than 0.3 mm at full load capacity of the machine.

- PID loop update rate – 8kHz.

- Data acquisition rate from the controller to PC of 15kHz (50kHz, 400kHz as optional) through 100Mbps ethernet connectivity.

- Crosshead speed ranges from 0.001 (0.0005 mm/min optional) to 508, 1016 mm/min (optionally available for higher speeds as well on request)

- Speed accuracy of 0.05% of the set speed.

- Series 7200 in integration with non-contact Advanced Video Extensometer supports measurement of true stress, strain, reduction in area, etc. Snaps can be taken during the tests and these snaps and videos can be downloaded easily from Advanced Video Extensometer for reference later.

- Simultaneous High-speed data sampling (for all analogue channels with) with different models of acquisition rate: 15kHz, 50kHz, 400kHz automatic or user-selectable.

- Position Control Resolution of 0.005µm.

- Travel resolution of 0.001mm (0.00001 mm, 0.00005 mm optional).

- Auto identification and digital auto-calibration of all sensor devices.

- Measurement accuracy of Load and Strain as per ASTM / ISO Standards.

- Auto stop/auto-return at the end of the test.

- Ready to use test procedure library as per industrial standards.

- Available models from load capacity 2.5kN up to 600kN.

- Extra height and width of the load frames and extra high or low-speed drive systems are also available.

-

Four Control Modes : 1) Travel – mm/min 2) Strain – (mm/mm)/min 3) Load – N/min 4) Stress – Mpa/min

-

Safe Jog Mode: Protects specimen, load cell and grips during crosshead positioning (even at high speed) as the crosshead instantly stops upon sensing the force on the load cell. This relieves the user from the stress of careful positioning of the sample and any possible load cell damage during this process.

-

Sample Protection Feature: While gripping the specimen in the fixture (grips) tension or compressive force is exerted on the specimen. This may deform or damage the specimen, which may affect the test results. By enabling the protect specimen mode the crosshead moves so the load exerted on the specimen is within the set threshold.

-

Fine Position: This is a very important feature enabling precise control and positioning of the crosshead especially during delicate and sensitive testing.

-

Four jog speeds are available i.e they are from the highest speed of the machine to as low as 0.001 mm (these four jog speeds can be set as per the user’s requirements).

-

Follow Me Mode: Crosshead movement responds to manually pushing or pulling on the upper grip. Increasing force produces greater speeds, ideal for setups, quick and easy positioning during sample loading and unloading. (Link: www.youtu.be/KQKiNZYONc)

-

Interface to connect Mitutoyo Digital Gauges.

- Comes with optional Touch Console Panel, for remote observation & live view of the ongoing tests.

- Higher load accuracy range

- Increased data rate

- Improved speed accuracy

- Wider speed range

- Increased crosshead travel

- Integrated Ethernet interface

- Up to four-transducer control channels can be integrated into the console.

- Light-weight & sleek Touch Console.

- For operating the machine, view live graphs of the tests online.

- A high-resolution display is easy to operate where you can continuously observe and monitor vital measurements during pre-test adjustments as well as throughout the test on the 7 user-defined live displays.

- Additionally, real-time results are easily displayed throughout the test.

- Also conducting a test directly from the console permits the operator to remain in the test space.

- The user can also view the results and calculations without returning to the PC

- These features reduce repetitive motion and keystrokes between the control panel and PC

- An additional measuring Gauge can be attached to the system.

- This gauge measures the sample thickness and auto-feeds to the UTM software for direct entry in the data field.

The reproducibility of test results is significantly influenced by accurate & reproducible measurement of specimen dimensions; methods of determining the relevant dimensions are defined in the standards. - Digital micrometre & Vernier callipers can be used to measure the dimensions accurately.

- These gauges can also be used to measure compression or load deflection very accurately during test.

Basic Safety Package

•Mechanical Over Travel Limits •Emergency switch with Lamp •Over Load Safety Mode

Power Saving Mode

• Programmable Sleep - Auto Sleep mode Activation

• Power down mode - Auto switches OFF the complete system

Dual Mode Operation

Dual mode Operation

•For operating the machine view Live graphs of the tests online.

•With PC system - Storing the test results for analysis.

Software Key Benefits

• Follow Me Mode

• Four Control Modes

• Special Safety Features

•Formula Editor

• Report Customization

• Ready to use Tests

• Flexible Testing Units