Video Extensometer

NON-CONTACT EXTENSOMETERS

Contact Type strain measurement devices are used to measure the strain & elongation of the samples during the testing. While measuring these devices may have an adverse effect or influence the characteristic of the sample under test, especially in the cases of delicate samples.

The apparent stiffness of the test sample can be increase due to the direct operating force of the contact extensometer.

KEY Differentiator

While contact type strain measurement devices are used for determination of the strain & elongation of the samples under test. These could influence the material characteristic of the samples & hence have an adverse effect on the test results due to:

• Knife edges at the contact point which may cause premature cracking or rupturing.

• The apparent stiffness of the test specimen may increase due to the extensometer operating forces.

• The weight of these devices could distort the delicate specimen.

To overcome these shortcomings, the Advanced Non – Contact Video Extensometer has been devised for contact free measurement a high performance measurement device with high precision, accuracy & resolution during the tensile & compression deformations for all types of rubber, plastic, metals, composites & foils. It consists of no moving mechanical parts & hence is independent from any effects due to mechanical inertia or wear.

Accurate measurement of Axial & Transverse Strain is possible with the high resolution digital camera and high-tech image processing.

The resolution of the system ranges from 0.01μm to 10μm.

Use of special High resolution tele centric lens enables to achieve much lower resolution. e.g. a telecenteric lens of

• 50mm FP can give a resolution as low as 0.01μm & accuracy of +2.5μm for FOV up to 100mm.

• 25mm FP can give a resolution as low as 0.01μm & accuracy of +5μm for FOV up to 200mm.

500mm (20inch) – Essentially for testing Polymers and materials with High value strain up to break.

60mm (2.4inch) – Specially designed and recommended for testing of the small samples and specimens using special telecentric lens.

The AVE comes with a variety of FOV i.e. 25mm, 50mm, 80mm, 100mm, 150mm, 200mm, 300mm, 500mm & 1000 mm are available as required.

To know more in details about the below features you can download our E-Catalogue or contact us for further information:

- r & n VALUES – TRANSVERSE STRAIN MEASUREMENT

- iDs – IMAGE DIMENSIONING SOFTWARE – EASY SET UP & OPERATION

- SAMPLE MARKING AND DETECTION

- ELIMINATION OF ERRORS

- CAMERA

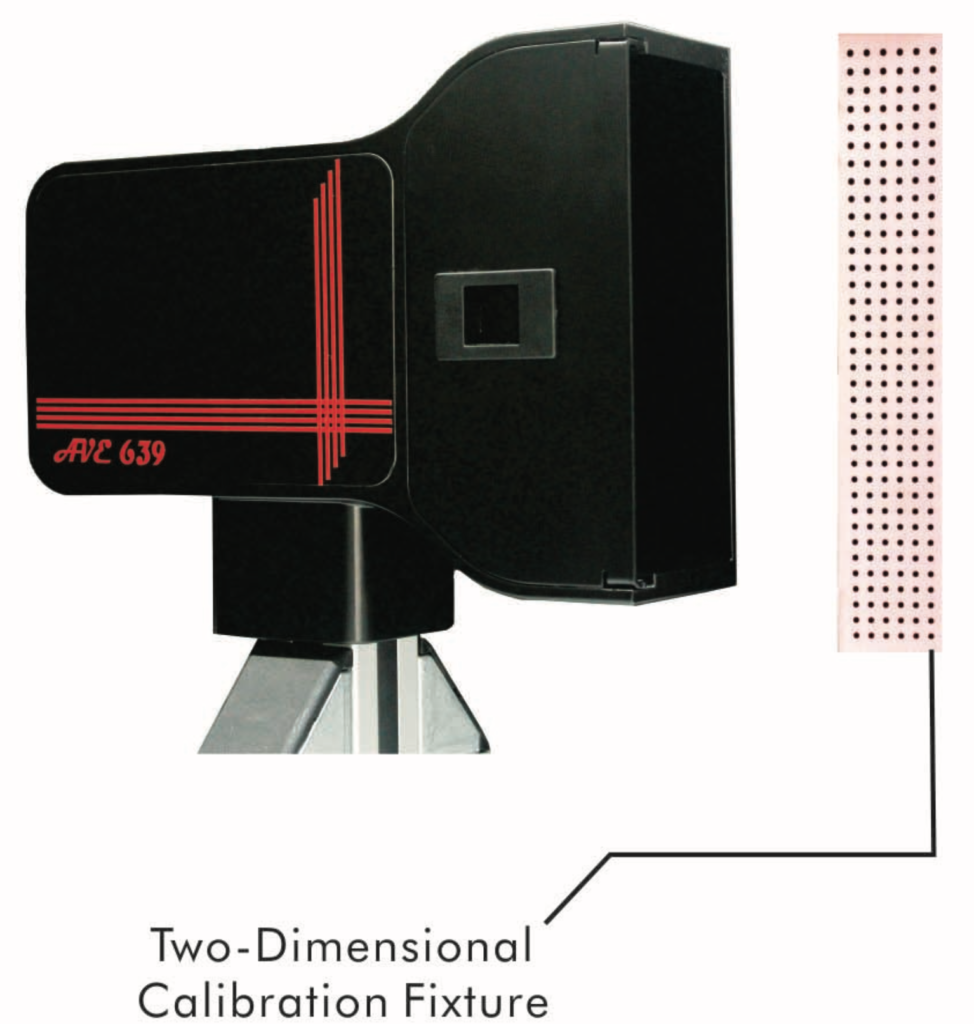

- TWO–DIMENSIONAL CALIBRATION

- LIGHTING AND ILLUMINATION

Series 7200 in integration with non-contact Advanced Video Extensometer supports measurement of true stress, strain, reduction in area, etc. Snaps can be taken during the tests and these snaps and videos can be downloaded easily from Advanced Video Extensometer for reference later.

"r" & "n" Values Transverse Strain Measurement.

The AVE comes with an option for transverse strain measurement, which enables the determination of "r" & "n" values according to ISO 101 13 &ISO 10275 & yield strength in tensile tests according to EN10002-1

Sample Marking And Detection

Specimen marking & mark detection and tracking of markers on the specimens for measurement is the basic principle of the non contact strain measurement.

Absolute Measurement Capability

The AVE functions by measuring the extension in absolute displacement units & percentage strain in contrast to the other non-contact extensometers, which are only capable of relative measurement

Lighting And Illumination

Various options & possibilities are available for the lighting or illumination of test setup for achieving optimum test results & meet the test requirement.